Introduction:

In today’s rapidly advancing world of electronics, miniaturisation is a key trend. Surface mount technology has revolutionised the way electronic components are mounted onto circuit boards, enabling smaller and more compact designs. One crucial component that has benefited from this technology is the surface mount switch. In this blog post, we will explore what a surface mount switch is, its benefits, and its applications.

Understanding Surface Mount Switches:

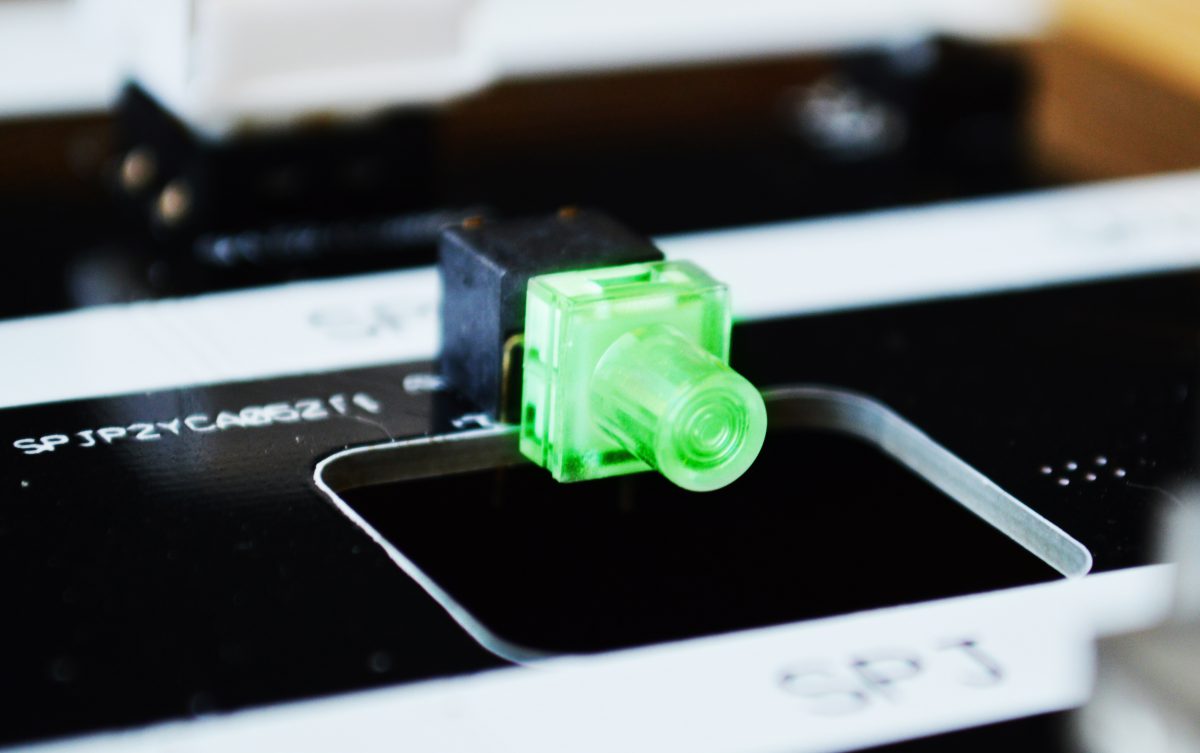

Unlike traditional through-hole switches, surface mount switches are specifically designed to be mounted directly on the surface of a printed circuit board (PCB). They are smaller in size, have a low profile, and offer numerous advantages over their bulkier counterparts.

Benefits of Surface Mount Switches:

1. Miniaturisation: Surface mount switches are tiny in size, making them ideal for space-constrained applications where size and weight are critical factors.

2. Improved Performance: These switches offer reduced electrical resistance due to shorter signal paths, leading to better signal integrity and enhanced overall performance.

3. Cost-Effective: The ability to automate their assembly process makes surface mount switches more cost-effective than through-hole switches, reducing production time and labor costs.

Applications of Surface Mount Switches:

Automotive Industry: From interior controls to safety systems, surface mount switches play a crucial role in automotive electronics, offering reliable and space-efficient solutions.

Medical Devices: The compact size of surface mount switches makes them ideal for use in medical devices where size and weight are critical considerations.

Industrial Automation: Surface mount switches find applications in various industrial automation systems, providing reliable control and sensing capabilities.

Factors to Consider When Selecting Surface Mount Switches:

1. Contact Style: Surface mount switches come in different contact styles such as tactile, rocker, and slide switches. Choosing the appropriate contact style is necessary based on the specific application requirements.

2. Actuation Force: The amount of force required to operate the switch should be determined based on the intended use and user experience.

3. Environmental Specifications: Consider the environmental conditions the switch will be exposed to, such as temperature range, moisture, and dust resistance, to ensure reliable performance.

Final Thoughts

Surface mount switches have become a ubiquitous component in various industries due to their small size, improved performance, and cost-effective production. Whether it’s consumer electronics, automotive applications, medical devices, or industrial automation, surface mount switches offer reliable control and sensing solutions in compact and space-constrained designs. As technology continues to advance, surface mount switches will undoubtedly play a vital role in shaping the future of electronics.

Interested in our products? Speak to us today!

How to place an order?

We operate Monday – Thursday (8 am – 5 pm) and Fridays (8 am – 4.30 pm)

Call us on +44 (0) 1234 213600 to speak to our Sales Engineers or e-mail us

on [email protected] alternatively, leave us a message using our online contact form.

View our full product range here | Download our recent product catalogue

Switch on.

Sign up to our mailing list for the latest news, product notification and so much more!

Just one click away…