The Pros and Cons of Robotics

The integration of robotics has been steadily increasing for a long time, but the global pandemic in 2020 caused a sudden acceleration as businesses looked for ways to improve cleanliness and support their workforce. Now, robots and automated machines are appearing more and more, as many companies across the scope of industries are looking for ways to improve efficiency, minimise risk and create more sustainable processes.

In this article we’ll investigate the positive and negative arguments for integrating robotics and automated machines into your business.

What sort of jobs can robots do?

1. Manufacturing

2. Construction

3. Inspection/Investigation

4. Healthcare

5. Cleaning

6. Food preparation

7. Vertical farming

8. Delivery/Transportation

The Pros of Robotics

Efficiency

By automating certain processes, you can increase the overall efficiency of your business. Robots are able to perform tasks more quickly than human counterparts and can be used at any time of the day, or even 24 hours a day if needed.

Cost-effectiveness

It is undeniable that introducing robotics into your business would be an investment, but in the long-run they will reduce your overall costs. One key reason for this is that mistakes are reduced when systems are automated, and therefore costly resources are wasted less.

Safety

If you have a task that is difficult or dangerous for a person to undertake (e.g. in a hard to reach area or with dangerous equipment), getting a robot to take over the job is a great solution. In addition, automated systems always have a fail-safe to stop accidents from occurring.

Supervision

Once the robots are up and running, they shouldn’t need the constant supervision that you might have to give to human counterparts. On the rare occasion that an issue does arise, most automated machines will have a way to notify you.

Operations

Implementing robotics into your business can help to improve your overall operational structure, as staff can be relieved of time-consuming tasks, allowing them to focus their attention on generating new ideas for your company.

Switches in Robotics

To reduce costs and increase efficiency further, these automated machines and robots need to be created using high quality and long-lasting components, so repairs and replacements can be minimised. This is where RJS Electronics comes in. Below are just a selection of the switches that we can supply to the robotics industry.

Our range of Metal Anti-Vandal Switches provide a sleek finish to any design, and have the added benefit of being hard-wearing against frequent use or accidental damage. These switches are IP rated and can be customised with a variety of material, LED illumination and etching options.

Any automated machinery should have an Emergency Stop Button, so that all operations can be immediately stopped in case of an accident or issue. We offer E-stops with ‘push-pull’ or ‘twist release’ functionality. These come in a variety of sizes, with LED illumination and IP rated options.

Rocker Switches are a common option for on/off switches in many applications. These are a great choice for smaller machines or robots that are wireless and therefore can’t be switched on from a separate control panel. We offer rockers in a range of shapes, sizes and colours, with LED illuminated options and symbols/text also available.

LED Indicators are a useful component to have in many applications, as they clearly signal to the user/operator when a machine or system is running, or as a warning when there is a fault. We supply plastic and metal indicators in a range of colours, sizes and illumination types, with IP rated and ultrabright options also available.

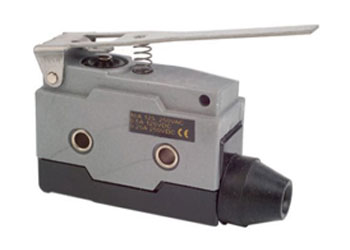

Limit Switches will only work when an object comes into contact with the actuator, making them particularly useful for robotics in applications such as manufacturing, or where extra safety parameters are required. We have limit switches with whisker, roller, lever or plunger-type actuators.

The Cons of Robotics

Initial Costs

Whilst utilising robots in your business can reduce costs in the long-term, the initial implementation may become costly. Alongside the cost of the actual robot and any software that goes with it, you may also need to redesign and restructure your workspace and/or processes.

Inflexibility

As robotics is still a relatively young industry, there are certain limitations to the actions that a robot can perform. So if you want to change or update your processes, it might be hard to reprogram the robots that you already have for new tasks.

Safety

Although in many ways the use of automated machines increases safety, they also introduce new hazards. Therefore, strict regulations and training must immediately be put in place when introducing them to a workplace.

Training

Alongside safety training, your employees will need general awareness training of how the machines work. You will also need to train some members of staff on how to operate the robots. Alternatively, you could hire pre-trained operators, but this will add additional costs.

In Conclusion

Taking into consideration the initial investments of time and money needed to implement robots and automated machines into your business, the long-term benefits should greatly outweigh any negatives.

If you are looking to create your own robots or automated machines, speak to our experienced Sales Engineers today to find out which switches are the best fit for your project.

Interested in our products? Speak to us today!

How to place an order?

We operate Monday – Thursday (8 am – 5 pm) and Fridays (8 am – 4.30 pm)

Call us on +44 (0) 1234 213600 to speak to our Sales Engineers or e-mail us

on [email protected] alternatively, leave us a message using our online contact form.

View our full product range here | Download our recent product catalogue

Switch on.

Sign up to our mailing list for the latest news, product notification and so much more!

Just one click away…